Conducting a reaction in a meniscus moved over a substrate

Description: There is a device and method for creating thin layers using a sliding meniscus. The system causes photo- and electrochemical reactions in a meniscus moved along the substrate. With the device, it is possible to obtain structures and layers from inorganic and organic materials with controlled shape, thickness and/or width on conductive and non-conductive substrates, including elastic substrates.

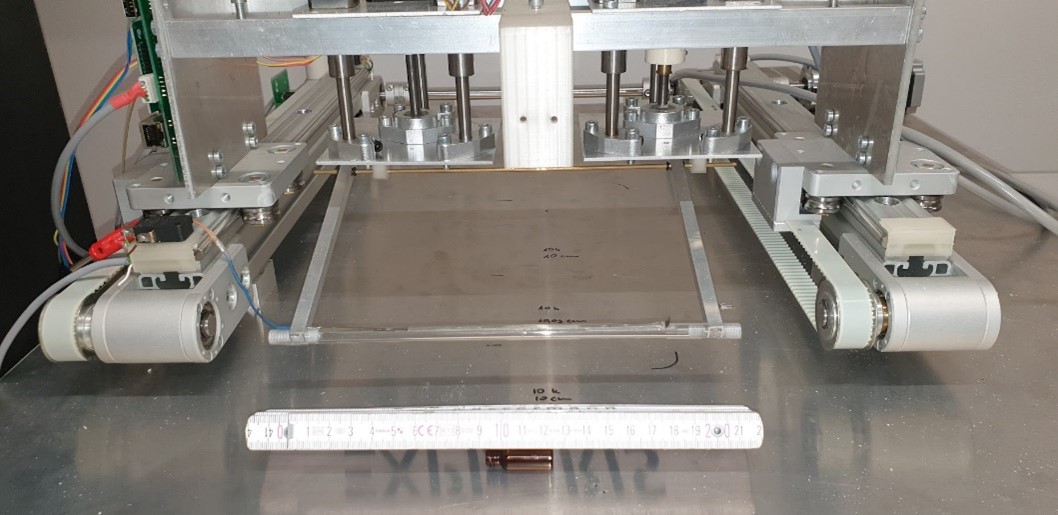

There is a device and method for creating thin layers using a sliding meniscus invented and developed by our scientists. The system causes photo- and electrochemical reactions in a meniscus moved along the substrate. The meniscus is created by the solution dosed between the roller and the substrate. By changing the speed of the roller relative to the ground and controlling the position of the roller above the ground, it is possible to produce controlled structures. What is an advantage, we can apply on a flexible substrate, efficiently and saving material costs - performing the reaction in the meniscus does not require immersion of the entire substrate in the solution, but only the application of a small amount of solution between the guide element and the substrate. With the device, obtaining structures/layers from inorganic and organic materials with controlled shape, thickness and/or width on conductive and non-conductive substrates (including elastic substrates) is possible. That might be large-format devices of “plastic” electronics and solar cells, antireflective surfaces, superhydrophobic coatings, protein microarrays, or cell culture media.

Organisation: Jagiellonian University

Innovator(s): Awsiuk Kamil, Dąbczyński Paweł, Michalik Maciej, Rysz Jakub, Budkowski Andrzej, Marzec Mateusz

Category: Nanotechnology, Materials & Engineering

Country: Poland