Safe and Green Recycling Methods and Procedures for Ships and Platforms

Description: Patent No.: CN201910194104.3

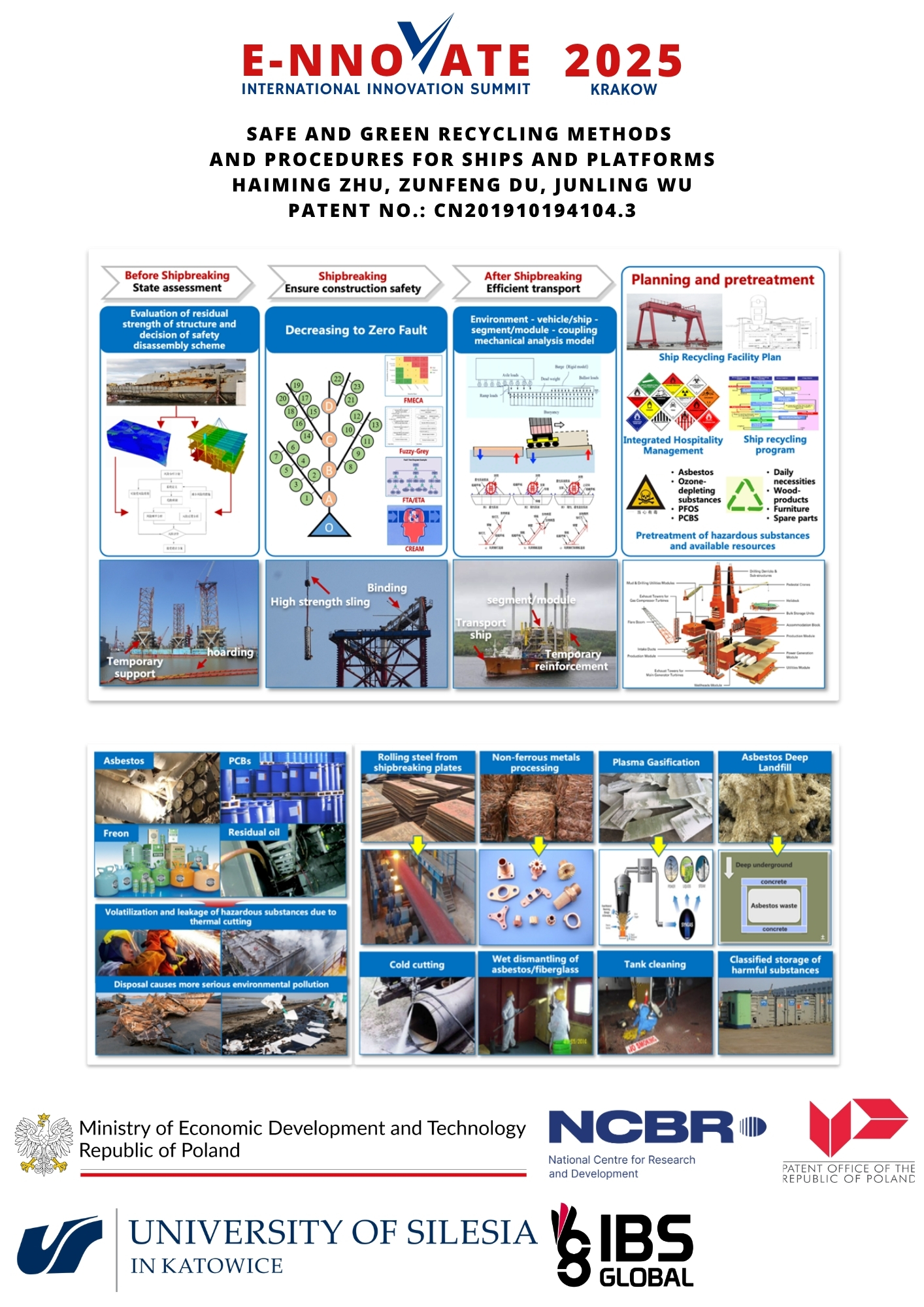

Introduction: Shipbreaking is a crucial part of the shipping industry, but it is plagued by pollution and safety concerns. Working with the world’s oldest shipbreaking research institute (Hu-Yunchang Ship and Marine Structure Recycling Technology Research Center at Tianjin University) and China’s largest and most advanced green shipbreaking facility (Chang Jiang Shipbreaking Yard), our team have developed a series of methods and technologies that promote environmental-friendly and safe practices in shipbreaking. Advantages and significance of the invention: 1. Our novel approach of ship recycling combines alongside and floating dock methods (Figure 1), including a comprehensive framework of safety assessment -based dismantling planning for marine structures that makes sure residual strength during the dismantling process, a risk management model named “Decreasing to Zero Fault”, key technologies of modular dismantling, lifting and transportation of large pieces. 2. An improved hazardous material management system based on the substance flow analysis method (Figure 2). Key technologies that avoids creating or leaking of hazardous materials in the first place, such as cold cutting, deep-processing and reuse of materials, plasma gasification. Key techniques for handling existing hazardous materials like asbestos, polychlorinated biphenyls, and fiberglass. Optimized layout of dismantling sites and standardized dismantling processes to effectively protect the environment and workers’ occupational health. 3. Methods for improving ship design based on feedback from the shipbreaking perspective (Figure 3). Advanced methods such as modular design and construction, virtual simulation, structure optimization, and using of environment-friendly materials. Social contribution and international evaluation: 1. We have successfully applied our invention to dismantle over 1000 ships and 20 offshore platforms, with remarkable environmental benefits. 13 million tons of high-quality scrap steel and non-ferrous metals were recovered, 4.11 million tons of standard coal and 22.59 million tons of water consumption were saved, 14.01 million tons of carbon emission were reduced, and economic benefits reached 6.428 billion yuan. 2. Our project is certified by international organizations like the IMO, EU, and ISRA, and is highly regarded by shipowners such as Maersk, and third-party supervisory agencies such as Sea2Cradle, Lloyd’s Register of Shipping, China Classification Society, and Bureau Veritas.

Organisation: Tianjin University

Innovator(s): Haiming Zhu, Zunfeng Du, Junling Wu

Category: Environment

Country: China