Intelligent Ship Screening and Stowage Method for Multiple Offshore Modules

Description: Patent No.: CN202110149883.2, CN201810089151.7, CN202110149868.8.

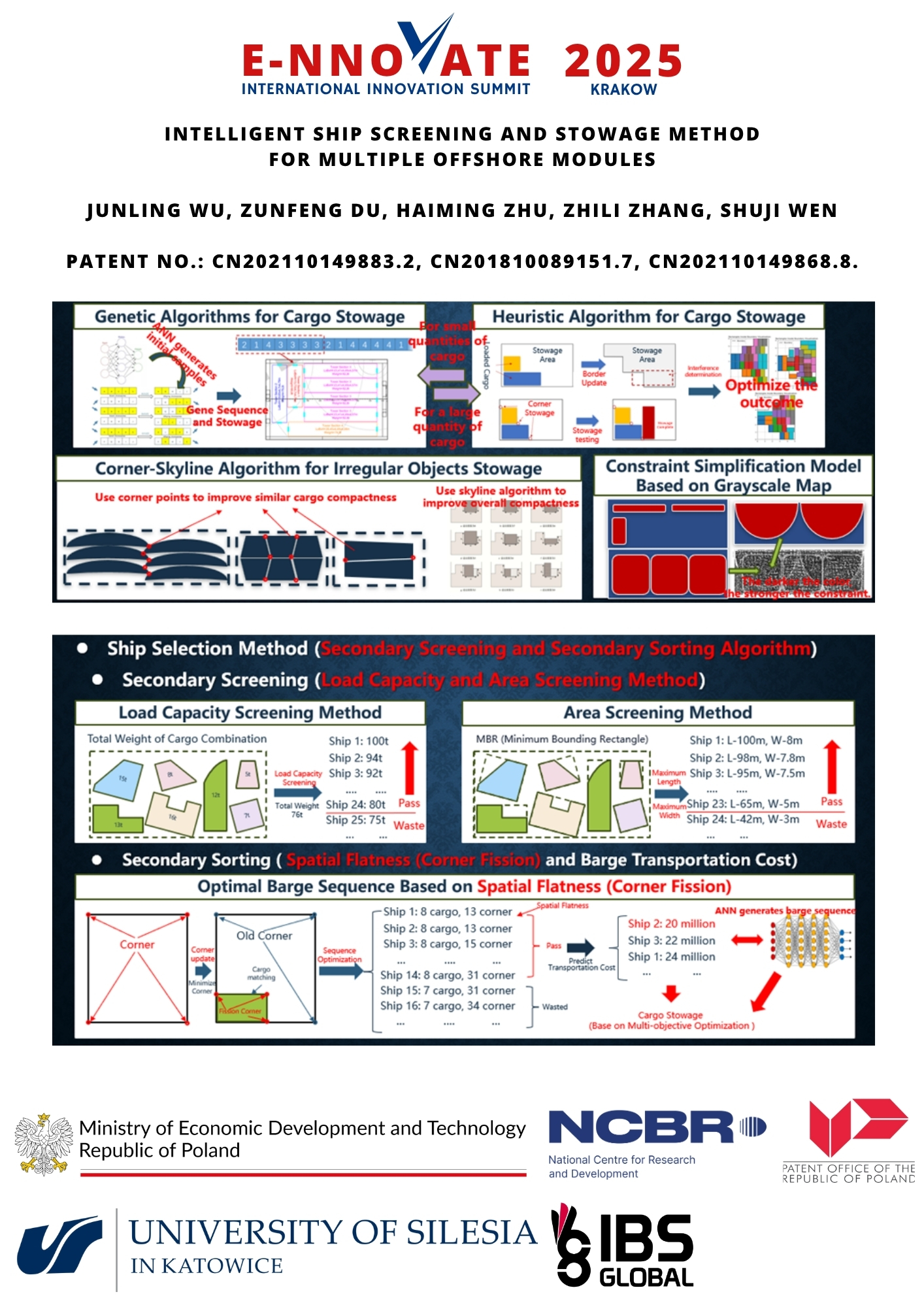

Introduction: Due to the diverse shapes, overweight mass, and large volume of offshore engineering modules, their maritime transportation loading has always been a complex and rule-intensive task, often requiring significant labor costs. The reasonable selection of shipping resources and cargo arrangement are crucial links and key technologies in maritime transportation loading. Our project team has developed a set of intelligent ship selection and loading technology for multi-offshore engineering module maritime transportation that aligns with engineering practice. By innovatively proposing the "secondary screening-secondary sorting" method and the "corner-skyline" loading algorithm, we have established a comprehensive loading solution from ship selection to cargo arrangement. Advantages and significance of the invention: 1) Innovative ship resource screening method: To achieve rapid ship resource screening, we innovatively propose the "secondary screening-secondary sorting" method. Through multiple screenings and sorting, ship resources can be quickly and accurately located (Fig 1). Based on the embedded ship resource database and cargo set information, the loading dimensions are obtained through the minimum bounding rectangle of the cargo. Available ships are selected through dual screening of weight and dimensions. Through secondary sorting based on spatial flatness and transportation costs, combined with corner point fission during loading, ships are initially sorted and then sorted again based on transportation costs. The ANN intelligent algorithm is applied to store loading information and ship information in model training. When the sample size is sufficient, the optimal ship sorting can be directly obtained, reducing algorithm operation costs. This method is simple and feasible, breaking through the existing design mode relying on designers' experience and repetitive "trial and error", optimizing design schemes, and improving overall efficiency. 2) Intelligent cargo loading solution: We have constructed an intelligent cargo loading solution based on genetic/heuristic algorithms and the corner-skyline algorithm (Fig 2). Through research on various loading conditions, we innovatively propose using genetic algorithms and heuristic algorithms to solve loading problems under different cargo quantities and spatial complexities. While considering algorithm speed, we ensure the accuracy and usability of loading results. Constraint conditions are simplified through grayscale maps, and the corner-skyline algorithm is used to achieve the densest cargo arrangement under various algorithm conditions. 3) Development of wind power intelligent loading system: We have developed a wind power intelligent loading system to achieve rapid ship selection and loading for wind power module cargo (Fig 3). The system is directly embedded in the company's original data information platform, integrating four modules: ship resource screening, intelligent cargo loading, loading/unloading design, and loading drawing output. It integrates the whole process decision-making functions of cost estimation, module loading design, and loading/unloading transportation planning for wind power module transportation. It achieves multi-department collaborative office work and data transmission, and allocates computing resources. Application and Economic Benefits: Based on this invention, we have published one academic work, obtained three authorized invention patents, and three software copyrights. This invention has been fully applied in demonstration projects of companies such as CNOOC and COSCO. It reduces annual personnel input costs by over 30 million CNY and creates over 3 billion CNY in benefits through voyage cost savings, demonstrating broad prospects (Fig 4) Development prospects: Based on this invention, it can not only solve cargo loading in traditional maritime transportation processes, such as offshore engineering modules, wind power equipment, ship modules, engineering vehicles, pulp bales, etc., but also solve related problems in other logistics fields such as warehouse cargo arrangement and aircraft cabin cargo loading. By setting complex constraint conditions, it can even complete product layout design, such as circuit arrangement of micro-robots, showing its wide range of applications.

Organisation: Tianjin University

Innovator(s): Junling Wu, Zunfeng Du, Haiming Zhu, Zhili Zhang, Shuji Wen

Category: Transport and Logistics

Country: China